How the ConDex System

Recovers 30%+ More Heat

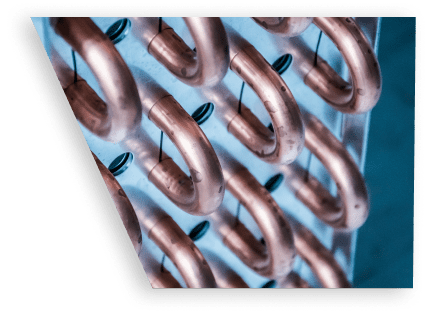

High Heat Transfer Capabilities

Simply put, we made the ConDex System capable of handling more extreme conditions than standard heat recovery systems. Proprietary metallurgy and a unique finned-tube configuration allow ConDex Systems to recover more heat from exhaust gas at temperatures in excess of 1000°F.

Condenses Water Vapour in Exhaust Gas

The high heat transfer ability of ConDex Systems cools exhaust gas below its dew point to recover a massive amount of energy that would otherwise be wasted. The heat recovered at 980 Btu/lb (544.88Kcal/kg), saves one cu.ft. (.28 cubic metres) of natural gas.

Corrosion Resistance

The ability to recover more energy by cooling exhaust gases to the point of condensation is facilitated by the high corrosion-resistant properties of the metals used in ConDex exchangers. They also require less maintenance, fewer repairs and have longer operating life compared to standard systems.

Smaller Footprint - Bigger Performance

The cylindrical ConDex System is dramatically smaller but far more efficient than standard systems. But its efficient size has no impact on the exhaust source, and it operates within with your existing processes.

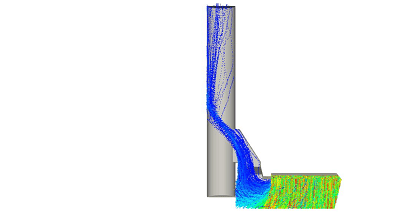

Patented Reverse-Flow Design

ConDex Systems are uniquely capable of cooling exhaust gases below their dew point due to their innovative, Clean-Tech patented reverse-flow design, which protects boilers from the condensate and the corrosion it causes.

Guaranteed Performance

Your ConDex system’s energy recovery performance is guaranteed. And we also guarantee our exchangers against corrosion from flue gas condensation.